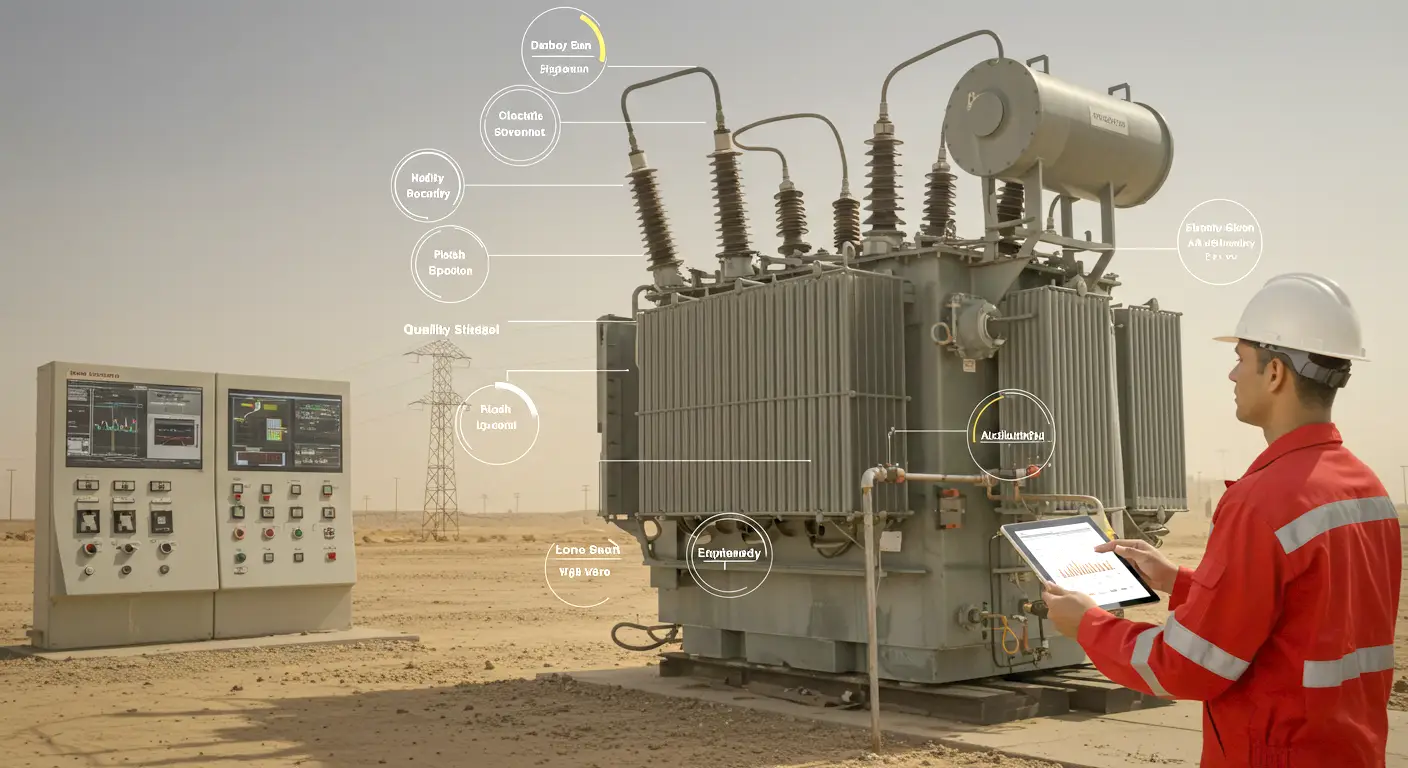

When it comes to transformers, the role of transformer oil (TO) cannot be overstated. As a key component in maintaining the operational efficiency and longevity of transformers, transformer oil plays a critical role in cooling, insulation, and preventing damage to the equipment. For businesses in the UAE and beyond, understanding the critical parameters of transformer oil is essential for selecting the best product to meet the demands of high-performance electrical systems.

In this blog, we will explore the critical parameters of transformer oil, why heat transfer is so crucial in transformer operation, and why working with a transformer oil manufacturer in UAE can ensure the best quality and performance of your equipment.

Understanding Transformer Oil

Transformer oil, also known as insulating oil, is used in transformers to provide electrical insulation, cooling, and help maintain the optimal operating temperature. Transformer oil is an essential part of a transformer’s cooling system, acting as a heat exchanger that dissipates the heat generated by the transformer’s core and windings. In addition to its thermal properties, transformer oil prevents the formation of dangerous gases and helps protect against electrical faults.

While transformer oil is a necessity for safe and efficient operation, the performance of transformer oil heavily depends on several critical parameters. Let’s break down these essential parameters to better understand how they impact the functionality of transformers.

Critical Parameters of Transformer Oil

-

Dielectric Strength

Dielectric strength refers to the oil’s ability to withstand electrical stress without breaking down. A high dielectric strength ensures that the transformer oil can effectively insulate electrical components, preventing short circuits and electrical faults.

- Why It’s Important: The dielectric strength is essential for the safe operation of transformers. If the transformer oil’s dielectric strength is too low, electrical breakdown can occur, leading to transformer failure.

- How It’s Measured: Dielectric strength is measured by applying an electrical voltage across the oil and determining the voltage at which it fails. For transformer oil, a dielectric strength of at least 30 kV per 2.5 cm gap is ideal.

-

Viscosity

Viscosity is the measure of a liquid’s resistance to flow. Transformer oil with the right viscosity ensures proper cooling and circulation through the transformer, helping to regulate temperature effectively.

- Why It’s Important: Transformer oils with high viscosity may flow too slowly, which can impair heat dissipation and lead to overheating. Oils with low viscosity may not provide adequate lubrication, increasing the risk of wear and tear on transformer components.

- How It’s Measured: Viscosity is measured in centistokes (cSt), and an ideal transformer oil should have a viscosity range that balances flow with cooling efficiency.

-

Pour Point

The pour point refers to the lowest temperature at which transformer oil remains in a liquid state and can continue to flow. This is particularly important in colder climates, where transformer oil may solidify and cause blockages or insufficient cooling.

- Why It’s Important: A low pour point ensures that the oil remains fluid and continues circulating even in cold temperatures. If the pour point is too high, the oil may become too viscous at low temperatures, reducing its ability to effectively cool the transformer.

- How It’s Measured: The pour point is determined by cooling the oil in a standard test and recording the temperature at which it no longer flows.

-

Flash Point

The flash point is the temperature at which the transformer oil can vaporize to form an ignitable mixture with air. Transformer oil with a high flash point is crucial for preventing fire hazards and ensuring safety.

- Why It’s Important: A high flash point is essential for safety. If the flash point is too low, the oil can ignite easily, posing a fire risk. Transformer oils typically have flash points above 140°C to ensure safe operation in high-temperature conditions.

- How It’s Measured: The flash point is measured using a standard test where the oil is gradually heated and exposed to a small flame to determine the temperature at which it ignites.

-

Acidity and Neutralization Number

Over time, transformer oil can degrade due to heat and exposure to moisture, leading to an increase in acidity. This can cause the oil to break down, resulting in the formation of acids that can corrode transformer components.

- Why It’s Important: A low acidity or neutralization number ensures that the oil remains stable and does not cause harm to the transformer’s internal parts. High acidity can lead to corrosion, decreasing the lifespan of the transformer.

- How It’s Measured: The neutralization number is determined by titration, and transformer oils should have a low neutralization number to ensure minimal acidity.

Why Heat Transfer is So Important in a Transformer

Heat is a natural byproduct of the electrical energy conversion process inside transformers. Transformers generate a significant amount of heat during operation, primarily due to the resistance in the electrical windings and the magnetic core. Effective heat transfer ensures that the transformer remains within optimal temperature limits, preventing overheating and subsequent failure.

Role of Transformer Oil in Heat Transfer

Transformer oil plays an essential role in heat transfer by absorbing the heat generated by the transformer’s core and windings. The oil circulates within the transformer, transferring heat away from the components and dissipating it through the cooling system. Without this efficient heat transfer, transformers would overheat, leading to damage, inefficiency, and potential failure.

- Why It’s Important: Proper cooling through efficient heat transfer ensures the longevity and reliability of transformers. Inadequate cooling can lead to premature failure of insulation materials, increased wear on components, and even catastrophic breakdowns.

- How Transformer Oil Enhances Heat Transfer: The thermal conductivity of transformer oil directly impacts the efficiency of heat dissipation. The oil must maintain an optimal balance between viscosity and flow to circulate effectively, maximizing cooling while avoiding sluggish movement that might restrict heat exchange.

Choosing the Right Transformer Oil: Insights from a Transformer Oil Manufacturer in UAE

As a transformer oil manufacturer in UAE, we understand that selecting the right transformer oil is vital for ensuring the performance, safety, and longevity of your equipment. The harsh environmental conditions in the UAE, coupled with high-temperature operating environments, make it especially crucial to choose transformer oil with the right critical parameters.

Working with a trusted transformer oil manufacturer in UAE means that you can rely on high-quality oils that meet all the required standards for temperature stability, dielectric strength, and overall performance. Our oils are designed to withstand the extreme conditions of the UAE climate, ensuring your transformers operate smoothly and efficiently, even under the most challenging circumstances.

Conclusion

Understanding the critical parameters of transformer oil and why heat transfer is essential for transformer operation is crucial for maintaining optimal performance and avoiding costly breakdowns. From dielectric strength to viscosity, each factor plays a significant role in ensuring that transformers continue to function efficiently over their lifespan.

As a leading transformer oil manufacturer in UAE, we offer high-quality oils that meet the rigorous demands of the industry. By choosing the right transformer oil, you are not only ensuring the safety and longevity of your transformers but also optimizing their efficiency in heat management.